Introduction: The Queue You Can’t See, The Time You Can’t Get Back

Here’s a simple truth: most warehouse delays aren’t dramatic; they’re silent. The pallet stacker sits idle while people wait their turn, and the line grows. On a busy cross-dock, five minutes of pause per move can stack into hours each day, and studies often peg 25–35% of travel as “empty.” With an autonomous stacker forklift, that dead time can shrink because routes adapt in real time, not at shift change. One site I visited had great people and a decent WMS—yet they still lost throughput to bottlenecks (tiny ones, everywhere). So the question is simple: if the floor is mapped and the jobs are known, why do jams persist? — funny how that works, right? Let’s follow the flow and see where the old fixes fall short, then compare what’s next.

Where Traditional Stacking Trips Up

Why do bottlenecks persist?

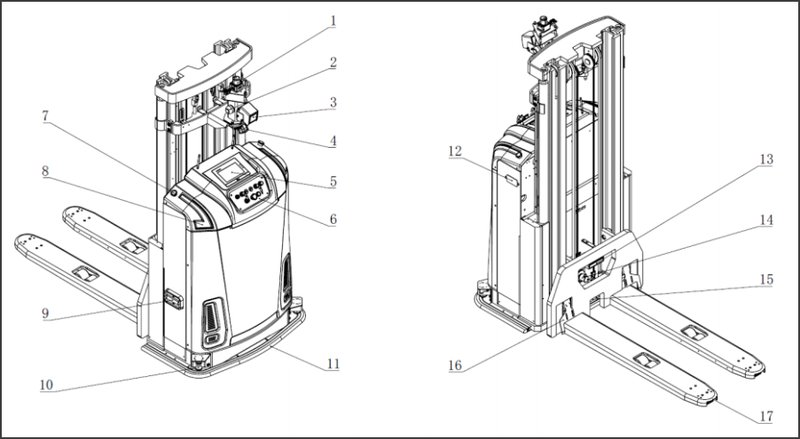

Let’s talk mechanics, not mystery. A manual or semi-auto stacker relies on a human to spot space, judge the load center, and align the fork carriage on the fly. That is skill, but it is also variance. Add tight aisles, mixed pallets, and peak-hour pressure, and the small errors stack. A tiny misread creates a re-try, a re-try becomes a pause, and a pause becomes a queue. Look, it’s simpler than you think: the system isn’t “slow,” it’s leaking seconds. Those seconds hide in turn radii, blind corners, and hand signals. They also hide in battery swaps when the battery management system (BMS) isn’t in sync with task timing.

Now layer in visibility gaps. Traditional setups don’t fuse signals from all moving parts. Sensor fusion is rare, so the truck can’t predict a blocked lane two racks ahead. Most fleets still run on fixed patterns, not live context. The result is stop-and-go traffic that nobody planned, and everyone feels. Even a sharp operator can’t see around a stack or past a tight endcap. The pain point isn’t talent. It’s information delay. And that is why small stalls turn into late picks and overtime.

Comparative Outlook: Principles That Change the Floor

What’s Next

Compare the old rhythm to the new: an autonomous stacker forklift reads the aisle like a living map. It uses SLAM to localize, updates paths as obstacles shift, and negotiates with other units on the fly. Instead of fixed routes, it rides policy: safety first, then shortest path, then energy use. Small but key difference. Edge computing nodes near the floor crunch sensor data fast, so the machine doesn’t need to “phone home” for every choice. That trims decision lag to fractions of a second— and you can feel it on the floor.

Think of it as traffic with turn signals that everyone can see. The system broadcasts intent, yields, and re-plans without drama. It keeps pallet geometry in view, so the load center stays on-spec in tight turns. Power use is not a side note either; power converters and the BMS coordinate charge windows with idle moments, not busy ones. Operators remain in the loop, but the loop is wider and calmer. People handle exceptions; machines handle routine flow. The vibe changes from “push through” to “move when clear,” and cycle times flatten out.

Choosing Wisely: Metrics That Matter

Here’s the practical takeaway before you pick a system. First, navigation fidelity: can the truck hold position within a tight tolerance at height, and maintain fork carriage stability on mixed pallets? Ask for measured error at the load center, not a brochure claim. Second, live throughput uplift: verify moves per hour during peak, not off-peak, and compare against your current WMS data—same shifts, same SKUs. Third, safety response latency: how fast do stops and slows trigger under mixed light and clutter, including cross-traffic? Bonus checks: battery swap or charge time under load, and data openness (CAN bus or API) for clean integration. Advisory, not hype: match these numbers to your floor plan and crew. If the fit is right, the small delays vanish first, then the big ones follow. For context and solutions in this space, see SEER Robotics.